Single use disposable plastic settler …

Familiar with our results on mammalian cell cultures using inclined and compact cell settlers as selective cell retention devices, senior scientists from a big biopharmaceutical manufacturing company encouraged us to develop these as single use disposable plastic settler devices for other applications, such as clarification of cell culture broth from a fed-batch bioreactor.

With funding from a new industry university consortium called NIIMBL (National Institute for Innovation in Manufacturing Biopharmaceuticals), a Dept of Commerce Manufacturing USA Institute, and collaborative support from the big biopharma company, we have now designed and fabricated the compact settlers as single use disposable plastic BioSettler. This NIIMBL Quick Start Project is titled “Scale-up studies on single use settlers for clarification of cell culture broth” and funds the fabrication and characterization of our single use settlers at three different sizes for perfusion and clarification applications over the next three years.

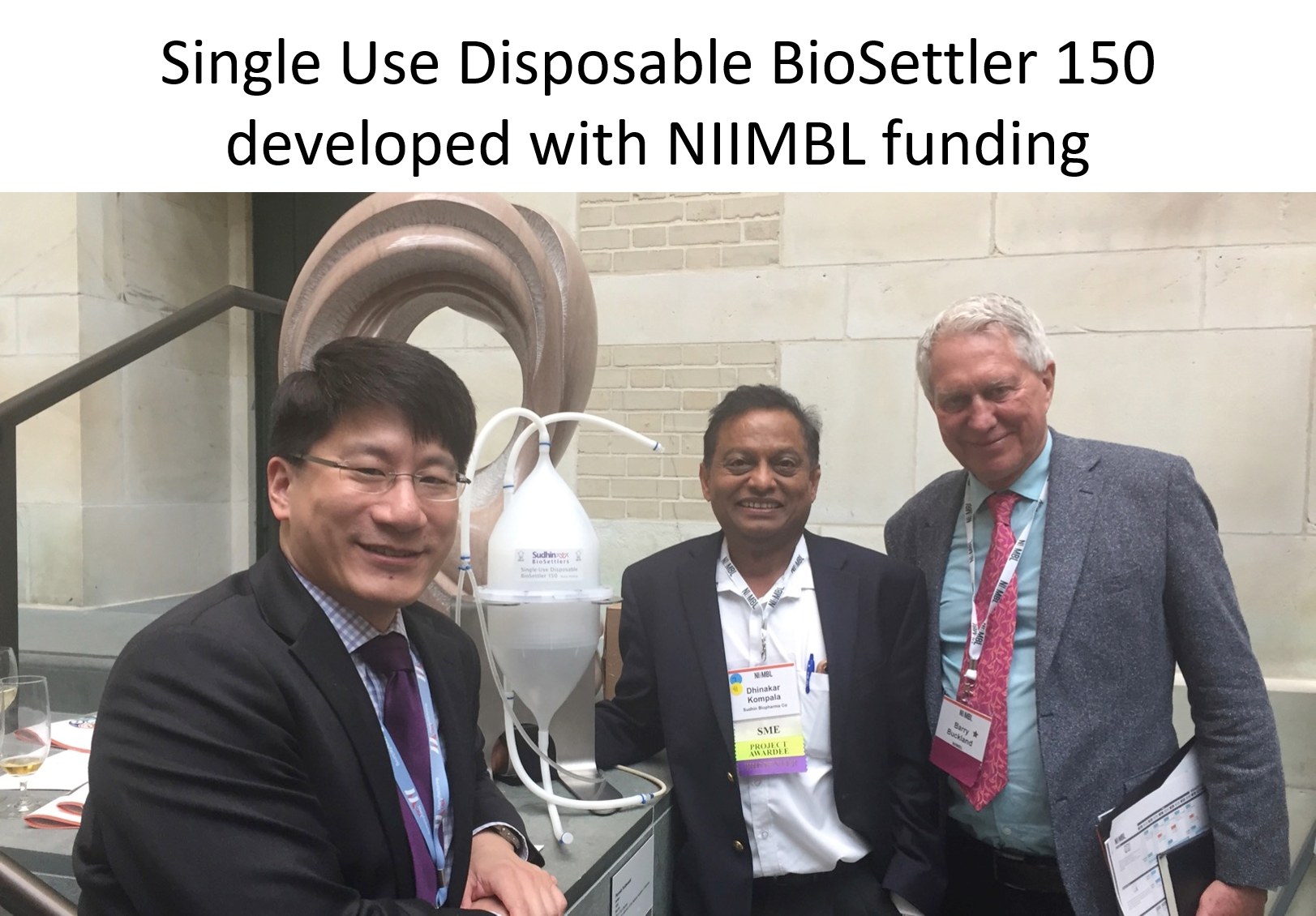

In the photo the first plastic settler is being launched at a national meeting of NIIMBL in May 2018, with Dr. Kelvin Lee, the Institute Director of NIIMBL, Dr. Dhinakar Kompala of Sudhin Biopharma and Dr. Barry Buckland, the Executive Director of NIIMBL at the National Academy of Sciences in Washington D.C..

Single Use BioSettler is useful as a selective cell retention device for perfusion bioreactor cultures of CHO cells

Sudhin Biopharma’s single use plastic BioSettler can be attached modularly to any bioreactor to remove dead cells and cell debris selectively and recycle live and productive cells back to the bioreactor, which therefore achieves high cell density and maintains high viabilities throughout the extended culture duration. The first available size of the settler is 6” in diameter, 18” in height, with a void volume of 3.8 liters. In the near future, we will make a smaller (3” diameter) and a larger (12” diameter) settler, as funded by the NIIMBL QSP grant.

In the photo, a stream of cell culture broth containing live and dead cells is continuously pumped via an “inlet” peristaltic pump into the plastic settler. The settled cells collected at the settler bottom central port are continuously pumped via the “return” peristaltic pump into the bioreactor at a slightly slower flow rate than the inlet. The dead cells and cell debris, which settle slower due to their smaller size are selectively removed via the settler’s top central port without the need for any pump at effluent flow rate, which is the difference between the inlet and return flow rates. The secreted product in the harvest stream can be quickly separated from the dead cells soon after they exit the settler/bioreactor even before they lyse to release their lysosomal enzymes to degrade the secreted protein products as they can inside extended fed-batch bioreactor cultures.

Selective removal of dead cells and cell debris from the perfusion bioreactor

Early perfusion bioreactor results from using the plastic settler are shown here. The viable cell densities reach 10 million cells/ml quickly and are maintained at that level during the 3 week culture period. After three days of initial batch culture, bioreactor contents are slowly fed into the settler is pre-filled with cell culture media, causing a slight decrease in the viable cell density (VCD) in the bioreactor due to dilution. VCD and the dead cell concentration in the settler return stream are higher than the bioreactor VCD and dead cell concentration due to the settling of both live and dead cells in the settler.

As perfusion rate is increased step by step to over 1200 ml/day, we can see more dead cells are removed in the settler top effluent than the larger live cells. The live cell concentration in the settler top effluent is >3 logs reduced compared to the inlet to the settler, which is the same as bioreactor VCD shown in this graph. In contrast, dead cell concentration in the effluent is only 2 logs reduced compared to the its bioreactor value. With such a big separation of live and dead cells in the effluent, the perfusion rate can be further increased to maintain high cell density and high bioreactor viability at even higher perfusion rates.

As there are no membranes to get clogged in our selective cell retention device, the perfusion bioreactor can be operated for much longer duration. Large scale inclined settlers have demonstrated for high cell perfusion bioreactor cultures operated for over 3 months. Our plastic settlers offer much higher (6x) settling capacity for the same footprint as the inclined settler and can operate more efficiently at larger scales.

Viability percentage in the bioreactor can be increased over time by using our plastic settler

Selective removal of dead cells and cell debris from the plastic settler at higher perfusion rates increases the viability percentage inside the bioreactor over time, specifically between weeks 2 and 3. This increase in viability percentage over culture duration is one of many useful features of using our plastic settler and is not seen with other (total) cell retention devices, such as membranes, centrifuges and acoustic devices.

This unique feature of increasing viability percentage can be useful in many other applications, such as in vitro expansion of CAR-T cells, which are often fraught with accumulating dead cells due to electroporation or longer expansion protocols. Another readily testable application of our settlers are in the separation of single cells and organoids (e.g. β islet cells) for many cell therapy applications.

Sudhin BioSettler for Cell Therapy Applications

Selective Removal of Dead Cells and Cell Debris to increase viability percentage in expanded CAR-T cells (e.g. Kymriah)

Harvesting, Washing and Concentration of many in vitro expanded cells in a closed, bench-top automated device.

Harvesting and Purification of ex vivo expanded MSCs after expansion on microcarriers and enzymatic detachment.

Harvesting of Organoids, such as the larger b cell islets,from smaller iPSCs and other differentiating cells.

Harvesting of Gene Therapy vectors (AAV) from HEK cells (being tested at NCState Univ through a NIIMBL SP grant).

Clarification of Cell Culture Broth from fed-batch culture (being tested at a big biopharma through NIIMBL QSP grant).

Selective Cell Retention Device for achieving high cell densities and viabilities in perfusion bioreactors (Sudhin).